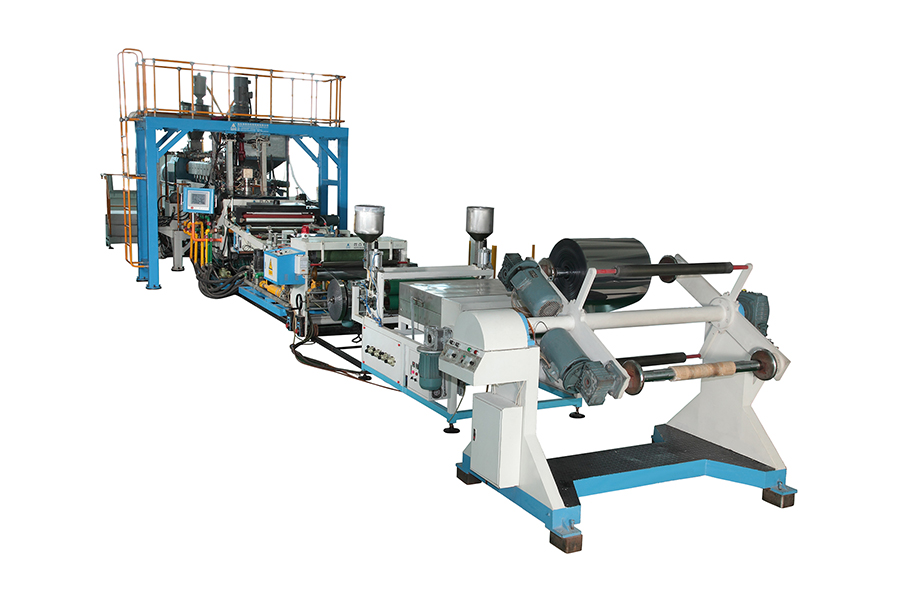

Twin Screw Plastic Extruder (PET Sheet Extrusion)

Technical Parameter

WJP(PET)75B-1000 Twin Screw Plastic Extruder (PET Sheet Extrusion)

| Zida zogwiritsira ntchito | Kufotokozera za screw | Makulidwe a mapepala | Mapepala m'lifupi | Extrusion mphamvu | Kuchuluka koyikidwa |

| mm | mm | mm | kg/h | kW | |

| APET, PLA | Φ75 ndi | 0.18-1.5 | ≤850 | 300-400 | 280 |

Mawonekedwe

1.The screw element itengera conjugate type double thread screw yokhala ndi makina okhathamiritsa apakompyuta ndi makina olondola. Kupatula apo, screw idapangidwa ndi ma multivariate kuphatikiza modular yomanga, yomwe imakhala yodziyeretsa komanso yosinthika.

2. Kutengera zaka zomwe zakhala zikuchitikira wononga kasinthidwe kamangidwe, AUTO akhoza kupanga mulingo woyenera kasinthidwe zinthu wononga zinthu mothandizidwa ndi ukadaulo wa mapulogalamu. Choncho, akhoza kuzindikira kufala kwa zipangizo plasticizing, kuyenga wosanganiza, kumeta ubweya ndi kubalalitsidwa, homogenization, volatilization ndi devolatilization, kusunga kuthamanga ndi extrusion ndi ntchito zina malinga ndi zipangizo kasitomala ndi processing luso.

3. Mtsuko wa makinawo umapangidwa ndi zolumikizira ziwiri zotulutsa vacuum zomwe zimatsimikizira kutulutsa mpweya wamadzi ndi mpweya wina wosakhazikika.

4. The mapasa wononga pulasitiki extruder lakonzedwa ndi Sungunulani dosing mpope kuonetsetsa kachulukidwe linanena bungwe ndi wokhazikika kuthamanga, amene angathandizenso kuzindikira basi kutsekedwa- kuzungulira kulamulira kuthamanga ndi liwiro.

5. Makina okwana amatengera dongosolo lolamulira la PLC, lomwe limatha kuzindikira kuwongolera kokhazikika kwa magawo, kugwiritsa ntchito tsiku, mayankho, zowopsa ndi zina.

Ubwino

Chimodzi mwazinthu zazikulu za mapasa athu opangira pulasitiki otulutsa ndi zinthu zawo zomangira. Kusamala kwakukulu kwachitidwa kuti zitsimikizire kuti zikuyenda bwino komanso zolimba mwa kugwiritsa ntchito sikona yolumikizana ndi twin-flight. Mapangidwe apaderawa amaphatikizidwa ndi ukadaulo wokhathamiritsa makompyuta ndi makina olondola, zomwe zimapangitsa kuti pakhale ntchito yabwino kwambiri. Zomangirazo zimakhalanso ndi kapangidwe kake kodzitchinjiriza kopambana komanso kosinthasintha. Izi zimatsimikizira kupanga kosalala komanso kosasokonezeka, kuchepetsa nthawi yopuma komanso kukulitsa zokolola.

Zaka zambiri pakupanga kasinthidwe ka screw zimatithandizira kupititsa patsogolo magwiridwe antchito a extruder. Mothandizidwa ndi ukadaulo wotsogola wa mapulogalamu, titha kukonza zophatikizira za screw element. Izi zikutanthauza kuti extruders athu akhoza efficiently kusamutsa ndi plasticize zakuthupi, kutsimikizira kusasinthasintha mkulu khalidwe linanena bungwe. Ukadaulo wathu wamapulogalamu umagwira ntchito yofunika kwambiri pakukwaniritsa magwiridwe antchito abwino, kuwonetsetsa kuti makasitomala athu amatha kupanga mapepala apamwamba kwambiri a PET.

Ubwino winanso wa mapasa athu opangira pulasitiki otulutsa ndi kusinthasintha kwawo. Kaya mukupanga pepala la PET lopakira, thermoforming kapena ntchito ina iliyonse, ma extruders athu amatha kukwaniritsa zosowa zanu zapadera. Imatha kukonza zinthu zosiyanasiyana, kukupatsani kusinthasintha kwakukulu pakupanga kwanu. Kuonjezera apo, extruders athu amapangidwa kuti asinthe mosavuta komanso mwachangu, kukulolani kuti musinthe pakati pa mitundu yosiyanasiyana ya mankhwala. Kusinthasintha uku kumakupulumutsirani nthawi ndi ndalama, ndikupanga ma extruders athu kukhala njira yotsika mtengo pazosowa zanu za PET sheet extrusion.