Multilayer Plastic Extruder (PP, PS, HIPS, PE Sheet Extrusion)

Technical Parameter

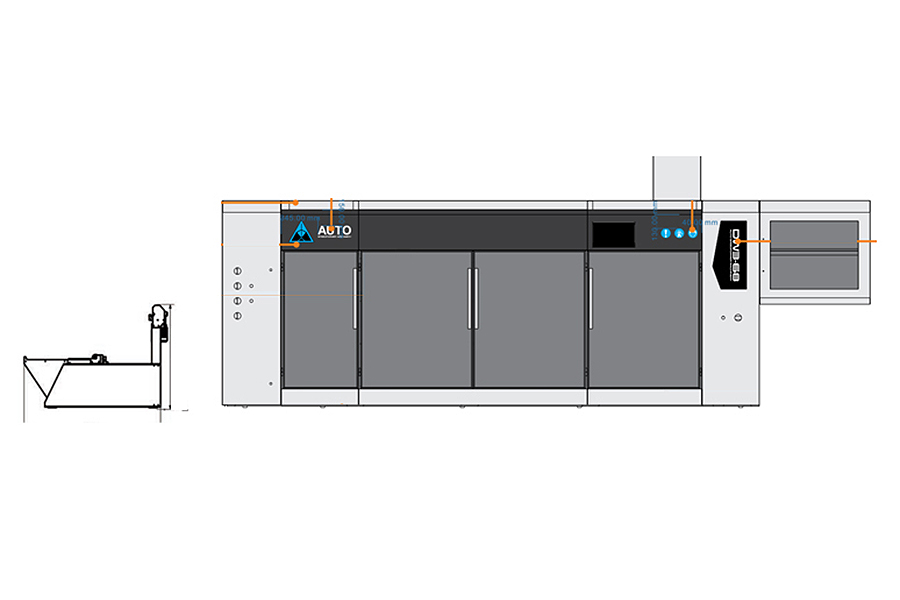

WSJP120/90/65-1000 Multilayer Plastic Extruder (PP, PS, HIPS, PE Sheet Extrusion)

| Nambala ya gulu | Kufotokozera za screw | Makulidwe a mapepala | Mapepala m'lifupi | Extrusion mphamvu | Kuchuluka koyikidwa |

| mm | mm | mm | kg/h | kW | |

| <5 | Φ120/Φ90/Φ65 | 0.2-2.0 | ≤880 | 300-800 | 380 |

Mbali

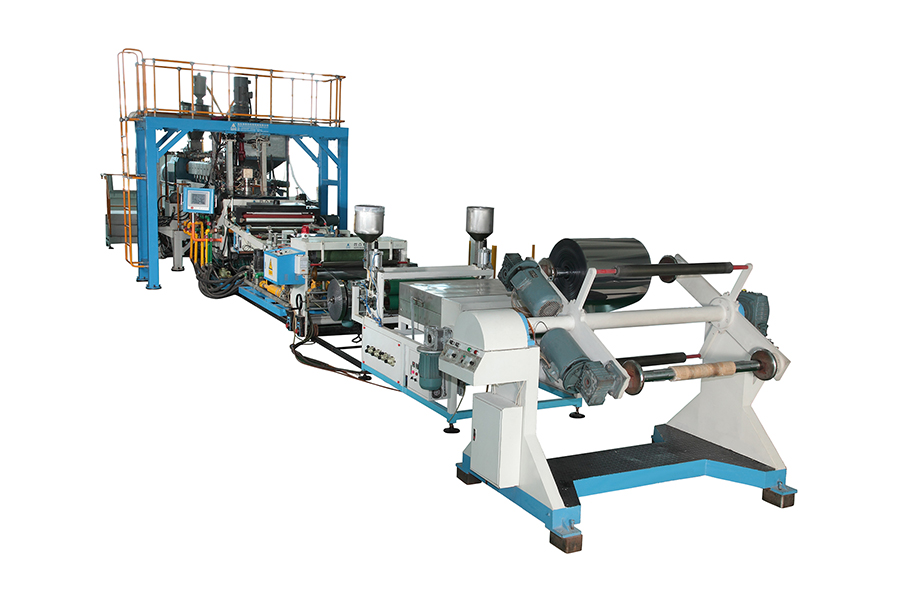

1. The single wononga pulasitiki extruder mu mzere kupanga utenga mtundu watsopano wononga dongosolo zimaonekera monga khola kudya ndi yunifolomu maphatikizidwe kusanganikirana, amene akhoza kuchepetsa mowa mphamvu ndi kuonjezera linanena bungwe kupanga.

2. The extruder pulasitiki utenga mwachindunji kugwirizana pakati galimoto ndi kuchepetsa magiya, amene angathe kusintha kufala Mwachangu ndi kuchepetsa kusinthasintha liwiro kuonetsetsa bata la extrusion.

3. Extruder idapangidwa ndi pampu yosungunula ya dosing ndipo imatha kugwirizana ndi ogawa osiyanasiyana. Mayendedwe a gawo ndi chiwongolero cha masamba onse amatha kusintha, zomwe zimatha kupangitsa kuti pakhale pulasitiki yofananira.

4. Makina okwana amatengera dongosolo lolamulira la PLC, lomwe limatha kuzindikira kuwongolera kokhazikika kwa magawo, kugwiritsa ntchito tsiku, mayankho, zowopsa ndi zina.

Ubwino

Pamtima pazatsopanozi pali pulasitiki yathu yopangidwa kumene ndi sikelo imodzi. Kusintha kwake kwapadera kwa wononga kumapangitsa kudyetsa kokhazikika komanso kusakanikirana kofanana kosungunuka, zomwe zimapangitsa kuti zinthu zikhale zabwino kwambiri. Mbali yatsopanoyi sikuti imangochepetsa mphamvu zamagetsi, komanso imawonjezera kwambiri zotulutsa. Ndi multi-wosanjikiza extruders pulasitiki, mukhoza tsopano kukwaniritsa apamwamba zokolola popanda kusokoneza khalidwe mankhwala ndi kusasinthasintha.

Chinthu chinanso chodziwika bwino ndi kulumikizana kwachindunji pakati pa mota ndi zida zochepetsera. Kulumikizana kwachindunji kumeneku kumapangitsa kuti kufalikira kwachangu ndikuchepetse kusinthasintha kwa liwiro, kuonetsetsa kuti njira yokhazikika ya extrusion ikhazikika. Pochotsa kusinthasintha kosafunika, ma multilayer pulasitiki extruder amatsimikizira kugwira ntchito kosasinthasintha, kuchepetsa nthawi yopuma komanso kukulitsa zokolola. Umboni wosasunthika, wosasokonezedwa extrusion ndondomeko monga kale.

Kuti tipititse patsogolo magwiridwe antchito, ma extruder athu apulasitiki amitundu yambiri amakhala ndi mapampu opangidwa bwino osungunuka. Kuphatikizika kwanzeru kumeneku kumagwira ntchito mosasunthika ndi makina owongolera bwino kuti akwaniritse bwino kagawidwe kazinthu ndikuchepetsa zinyalala. Tatsanzikana ndi kugwiritsa ntchito zinthu monyanyira komanso moni pakupanga kotsika mtengo.

Kusinthasintha kwa ma multilayer pulasitiki extruder ndi opanda malire. Makinawa amatha kukonza zinthu zosiyanasiyana zamapulasitiki kuphatikiza PP, PS, HIPS ndi PE kuti akwaniritse zofunikira zopanga zosiyanasiyana. Kaya mukupanga zonyamula, zomangira kapena zida zamagalimoto, ma multilayer pulasitiki otulutsa amatsimikizira zotsatira zabwino nthawi iliyonse.